The Product development phase (sometimes called Research and Development) of the Product Lifecycle is a scary and risky time for any company. The development phase is the first step of a product lifecycle and literally can make or break a project. Unfortunately some really great ideas fail to reach the hands of consumers simply because of poor project execution and planning during the initial phases of the lifecycle. Generally speaking a new product starts as a great idea or concept and with proper management and process, will grow into a well defined profitable product. The notion of product development and project execution can apply to anything from specialized medical equipment, a new robotic tool, an electric car, a new kitchen utensil, and even an app for your phone. Avoiding these 5 mistakes can help you get to market faster with a more reliability and profit.

Mistake #1: Not Setting A Realistic Budget and Timeline

“If you want it fast, it won’t be cheap.” It’s somewhat of a cliché but still holds true and it’s especially important to be realistic about your project needs and budget up front. Every few months we get approached by an individual or company that has an idea they want to bring to market as cheap and as fast as possible. During the initial consultations, one of the first questions I ask is: “When do you need it” followed shortly by “What is your development budget?” Invariably the answer is as soon as possible and as cheap as possible. Of course we do our very best to stay within a project budget, and it’s important not waste time/resources. However it’s just as important to do enough upfront engineering to be reasonably sure of success, while reducing the risk of failure to an acceptable level. If you swing the pendulum too far the other way by rushing and cutting corners, this will have catastrophic impacts on the long-term success and profitability of your product.

In-other-words, there is a definite correlation between the level of effort applied at the beginning of a new project, and the overall return on investment of the product. The trick is finding the perfect balance and knowing when to apply the right resources at the right time. Having experienced project management and engineering leads that know how to throttle the effort, is the key to successfully executing a project, with as little wasted time and money as possible. The best investment you can make at the beginning of a project is to bring in people that can do that for you.

Mistake #2: Diving into 3D Modeling

Design and engineering tools are easily accessible, and these days, every mechanical and aerospace engineering graduate out of college can perform basic design using 3D CAD software. The excitement of the new idea makes it hard to avoid temptation to dive right into modeling, but don’t do it. Starting the 3D model as the first step in your development often leads to getting emotionally and financially invested in a bad design that doesn’t meet the needs or intent of the original idea. The temptation for startups to immediately start creating models is further exacerbated by inexperienced designers flooding the market on freelance platforms offering “Engineering” or “Design Services” at hourly rates well below the average hourly pay for a seasoned designer.

The tasks needed to complete a successful design for the project will be multi-disciplined and will be a team effort. The more complex the product is, the more functions need to be involved. Therefore, diving into 3D CAD before the project has enough definition and framework in place to keep the design in check is project tunnel vision and should be avoided. Having the discipline to know when to begin the 3D modeling is an important aspect of a good project lead. Though there may be times when sketching or roughing out some initial concepts can be very valuable to the overall project success. For example: showing your idea to investors with a 3D model can often generate excitement about the project and may help with further development funding. But be careful how far you take those initial concepts before you step back and do proper development.

Mistake #3: Not Properly Managing Technical Data

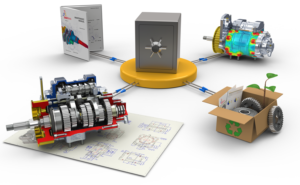

During the design and modeling process, changes to the 3D model are extremely frequent and mismanagement of the changes will often lead to downstream quality issues and/or even project failure. Software packages like CREO, Solidworks, CATIA, NX; are wonderful tools to create 3D models and drawings. However CAD software is usually a one trick pony and cannot help you with managing that data once you create it. Most companies are quick to invest in CAD packages but try to save money by not implementing a PLM system like Windchill, TeamCenter, SmarTeams, or Solidworks PDM.

You may hear terms like “Configuration Management”, “Engineering Change Process”, and “Release and Change Workflow” being used when talking about the management of technical data. These terms describe important aspects of managing technical data for the overall lifecycle duration. It can certainly be done with out a dedicated PLM software, but it requires extreme discipline and organization to keep up with all the changes.

Sadly even in large companies, It’s not uncommon for a design team to be working on a 3D model of a new product, and doing a “save as” at the end of the day with an appended date on the file name into a shared folder. I’ve been on design teams where the data management was the “save as” in a shared drive method, and It was a lesson in what not to do. While initially the cheapest solution out there, It also led to a ton of issues and mistakes. We spent countless hours having to remodel something because inevitably someone would save over a known good version by accident. I’ve also seen design mistakes propagate all the way to production because someone opened up an older version of a file and accidently saved it as the new version. In the long run, the cost to pay a few engineers salaries for countless hours of fixing mistakes would have been well worth the cost of a PLM system.

Because of the fast paced nature of the development project, it’s easy to lose track of model changes and other technical information, especially when you have multiple people working on a large assembly. This often leads to mistakes or unintended aspects being incorporated into a design, or at the very least, wasted effort having to correct mistakes further into the project. A good PLM system will not only store CAD data, but also track changes, manage workflows, help generate a Bill of Materials and help with configuration management. The ideal solution is one that is fully integrated with your CAD package. If you don’t have a PLM system in place, consider making that your next investment or work with a design company that already has one. At Sollows Technical, we utilize Solidworks PDM, which allows us to manage customer technical data with ease.

Mistake #4 Not Knowing What Good Enough Looks Like

There is no such thing as a bad design, just bad requirements and there is an entire discipline called Systems Engineering dedicated to the task of defining and managing requirements. If you’re a one person company or an inventor, and you’re controlling every aspect of the design; you might get away with not explicitly stating the design requirements. But once there are more than a few people working on a project; it becomes imperative to communicate what the “thing” should look like and how it should behave. In many instances, the stakeholders (Clients, managers, sales, etc) are the ones with the vision about what the new product should do. This is where it’s critical to create a framework around the design in the form of good requirements that are well written and well defined. Well defined requirements shall be validated, and requirement satisfaction shall be verified through any number of methods. This is known as Validation and Verification (V&V)

Without a proper requirements driven design, you will end up with one of two scenarios. The first is where the designer will think they understand what the stakeholders want, only to end up heading down a completely wrong path. The second scenario is when the stakeholders don’t really know what they want, and designers end up in an endless cycle of changes and scope creep, or over engineer a product making it more costly than what would normally be necessary. The goal of requirements driven engineering is to define what is good enough, and it’s actually harder than you’d think. It takes some upfront resources and discipline to execute requirements driven design; but long-term cost savings are well worth the effort.

Mistake #5: Developing Without Process

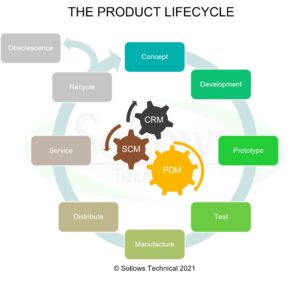

Lack of process is likely the source of nearly all the churn and waste in a company. Everything from quality and manufacturing issues, cost overrun, production stoppages and much more. And just about all the mistakes mentioned above could be avoided with the implantation of a good development process. A Product Development Process (PDP) is a pre-defined systematic approach that helps take the product from idea to manufacturing. It’s also the first half of a product lifecycle.

A well designed PDP that’s tailored for the size and needs of the project will facilitate communication among various stakeholders, allow for better planning and budgeting, it will include quality gates, milestones, and a project schedule that can show critical path items when needed. It will also help you uncover chokepoints and waste. Think of the PDP as care and feeding instructions for a fledgling new product. Even small design projects can have some aspect of a PDP. At a minimum, having a design review milestones and doing some requirement V&V would be the very basics.

Most established companies have some sort of unwritten development process even if they don’t realize it, because humans are creatures of habit and we like structure. But formally documenting that process is likely going to be one of the most valuable contributions you can do for your company. Once the overall PDP is defined, it can be used with all future development projects. However, projects are usually not a once size fits all and you can’t be afraid to lean out or add to a PDP as needed.

Conclusion

Improving on any of the 5 items mentioned above will not only have positive impact on your company’s margins but will also be important steps towards Lean and ISO 9001 certifications. At Sollows Technical, we developed our company from the ground up with process and efficiency in mind so that we can offer a plug and play solution to many of these common issues. Let us show you how we can help.